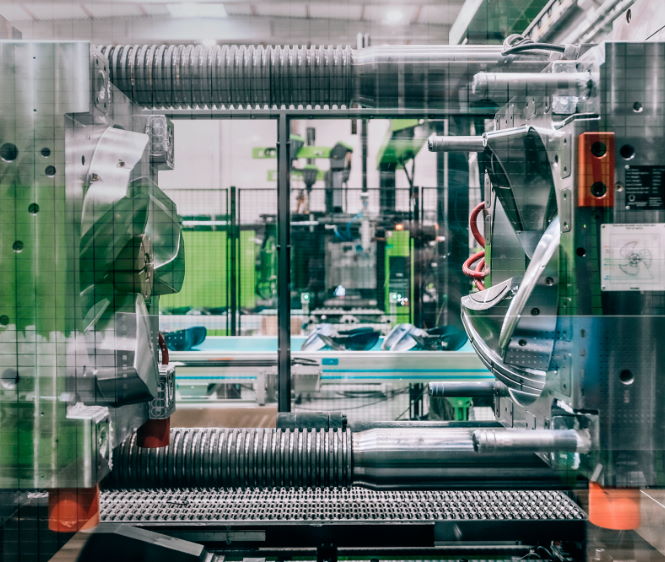

Plastic injection

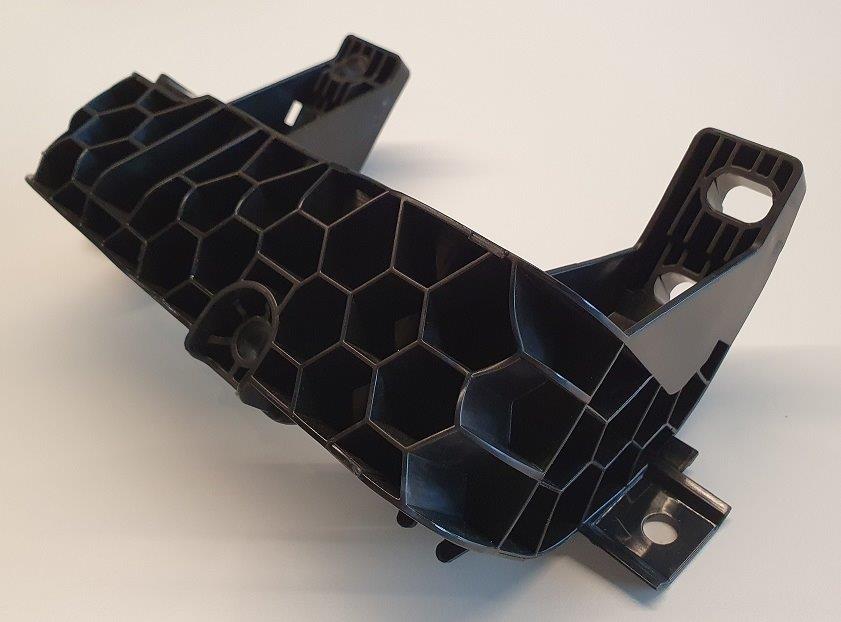

High quality custom plastic parts

Based on your 3D design or technical drawings, we take care of the production of your plastic parts. Innovation is key in this process. Our plastic injection shop is equipped with advanced, fully automatic injection moulding presses, suitable for both large batches and small, specialized series. Short cycle times and SMED ensure a fast and competitive flow. Our plastics department works closely with the tool shop and R&D department, providing a total solution from first design to finished product. There are multiple inspection points throughout the production process. This way, we ensure that the final product meets your requirements perfectly and results in zero defect deliveries.

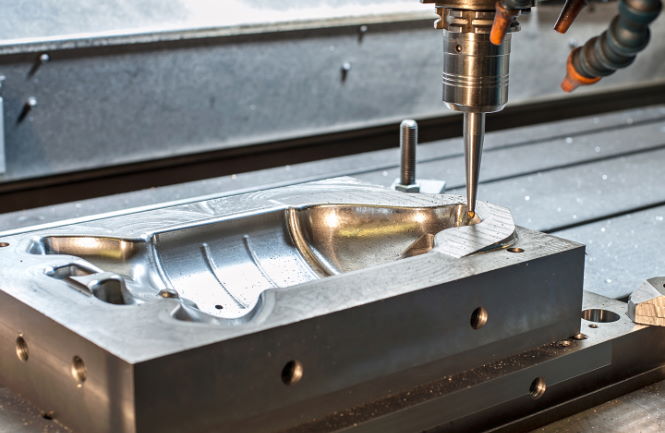

In-house design and manufacturing

The knowledge accumulated through the mass production of pieces in metal is transferred to our plastic production department, and vice versa. This way of thinking takes us closer to our goal once again: zero defects! The synergy between 3 completely distinct departments results in a true one-stop shop.

– Frans Penne / CEO –