Stamping dies

Progressive, deepdraw and transfer stamping dies

We design and produce progressive, deepdraw and transfer stamping dies. Both the production and the design of the die play a crucial role in the efficiency of mass production as well as the quality of the final product.

Progressive die stamping uses a sequence of stamping stations and is ideal for large series of metal parts. In addition, the process is highly repeatable and accurate. Each step in the process performs a different cutting, bending or stamping operation on the metal, gradually achieving the desired shape and design. It is also a faster process, while minimizing the amount of scrap.

In-house design and production

Penne designs and produces dies in-house. This is the only way to guarantee the customer a perfect end result with optimal production efficiency.

– Frans Penne / CEO –

Designshop: we design your die

Our design department works closely with our customers. Starting from an initial 3D design or functional description of the desired pieces, our specialized tooldesigners get to work.

Using advanced design software and 3D models, we work out a functional version of the pieces and the necessary dies. These can be evaluated by our customer’s technical services and adjusted as needed at any time. Such in-depth preparation paves the way for fast and secure production.

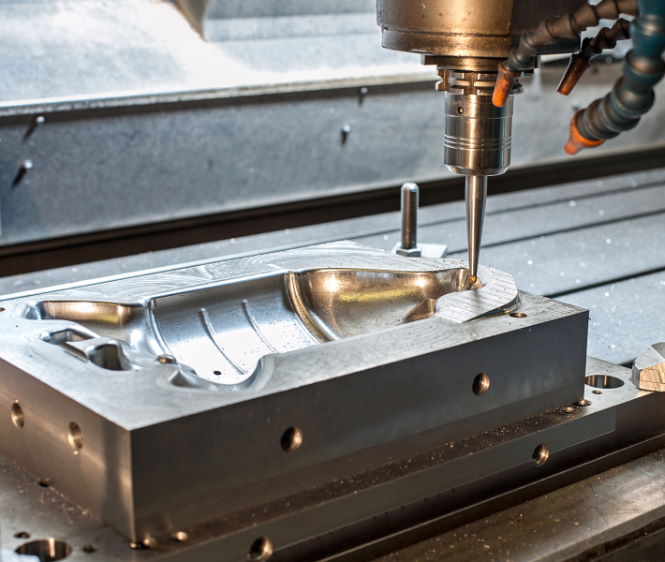

Toolshop: we manufacture your die

We manufacture all required tools and dies in our own toolshop. The continuous feedback and communication with the production department is an essential added value. This way, we maintain total control over the entire process and can guarantee the best quality of your metal and plastic parts. Our designers and experienced tool makers are well versed in the entire process of making state of the art tools.